Automotive Machine Service Shop

Plainfield, Naperville, Bolingbrook, IL

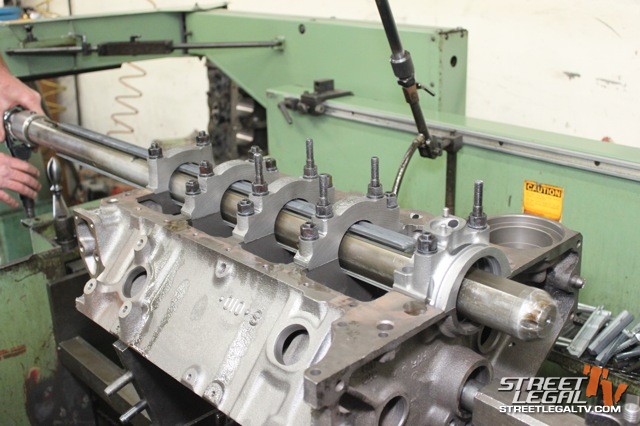

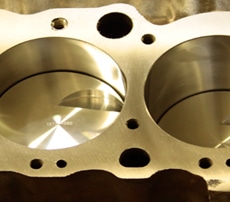

When an engine is machined or assembled at Last Chance Auto Repair, there are very tight tolerances, specs and machining knowledge that goes into every project. Engine parts are made more accurately so that everything fits to perfection. Helping the engine achieve its maximum potential power and it also helps reduce wear. When parts are too big or too small, power can be lost due to extra friction or to pressure leakage through bigger than necessary gaps. There is no room from error in the auto machining field of the engine world. The automotive cylinder block is a machined casting or sometimes an assembly of modules containing cylindrically bored holes for the pistons of a multiple cylinder reciprocating internal combustion engine.

You think it up, we’ll build it up!

Cylinder Boring, Engine Rebuilding, Engine Balancing

Last Chance Auto Repair is a full service automotive machine shop specializing in custom engine rebuilding, engine balancing, cylinder boring, aluminum cast iron head repair, competition valve jobs and vintage flat heads. Probably the most stressed part of the engine that is under constant high load and subjected to continuous changing forces is the connecting rods which plays no small part in an engines cycle. With the small end connected to the piston wrist gudgeon pin and the big end connected to the crankshaft both the geometrical alignment and the surface quality and roundness of its bearings are critical for good all out performance.

Performance Engine Rebuilding Service Expert

When building a high performance engine in the Last Chance Performance Machine Shop great attention is paid to the connecting rods, eliminating the stress risers by such techniques as grinding the edges of the rod to a smooth radius, shot peening to relieve internal stress, balancing all con rod piston assemblies to the same weight and magnafluxing to reveal otherwise invisible small cracks which would cause the rod to fail under stress. In addition, great care is taken to torque the connecting rod bolts to the exact value specified. Often these bolts must be replaced rather than reused, better safe than a costly come back. The big end of the rod is fabricated as a unit and cut or cracked in two to establish the precision fit around the big end bearing shell. Therefore, the big end caps are not interchangeable between con rods, and when you rebuild an engine, care must be taken to ensure the caps of the different connecting rods are not mixed up. Both the con rod and its bearing cap are usually embossed with the corresponding position number in the engine block.

Cylinder Head Machine Shop Serving Plainfield, Naperville, Bolingbrook, IL

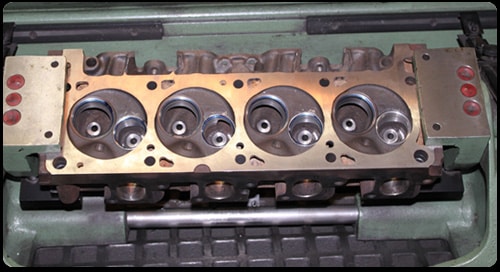

Cylinder Head – An internal combustion engine consists of a cylinder head that sits above the cylinders on top of the cylinder block. The closed, often detachable, end of a cylinder in an internal combustion engine. The cylinder heads house the intake and exhaust valves, the valve springs, the rocker arms and the spark plugs. Every cylinder head has at least two valves for each cylinder. Not all cylinder heads are designed the same way.

• Race application cylinder head rebuild expert

• Domestic and import engine specialists

• Custom automotive engine rebuilding

• Cylinder head machining rebuilding

• Cast iron cylinder head repair

• Competition valve jobs

• Spark plug extraction

• Custom machining

• Vintage flat heads